Small foodservice businesses operate in an environment where every percentage point of margin matters. Unlike large chains with their purchasing volumes and negotiating power, independent restaurants, cafes, and bakeries must find a balance between product quality and tight budget constraints.

Disposable supplies — packaging, disposable tableware, paper products, cleaning supplies — are often perceived as unavoidable fixed costs. In practice, competent procurement management can free up a substantial portion of the budget without any impact on service or product quality. The difference between chaotic “as-needed” purchasing and a well-thought-out supply strategy translates to thousands of dollars annually.

Analyzing Disposables Cost Structure

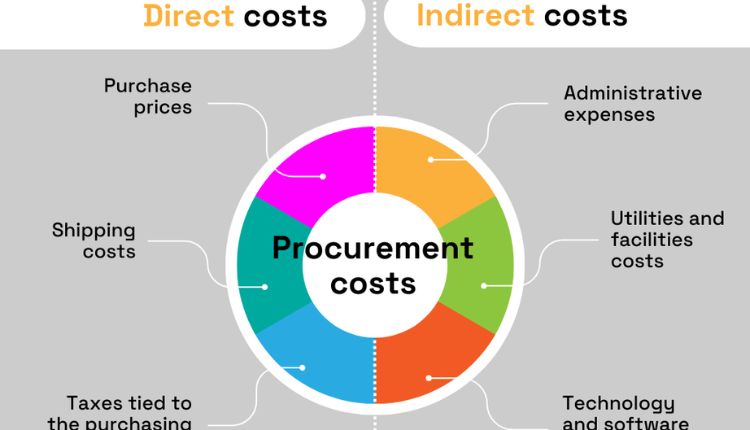

The first step toward optimization is understanding the actual cost structure. Without detailed tracking, it’s impossible to identify potential savings zones or discover inefficient purchasing patterns.

Main categories of disposable expenses in foodservice establishments:

- Takeout and delivery packaging — containers, bags, and cutlery comprise a significant share of costs, especially for establishments with active take-out segments.

- Paper products — napkins, towels, toilet paper, and parchment paper for baking require constant replenishment.

- Disposable tableware and serviceware — cups, plates, and utensils for quick-service establishments.

- Cleaning supplies and sanitary materials — detergents, gloves, and trash bags.

- Specialized materials — depends on establishment format and menu specifics.

A detailed audit over the past three months typically reveals unexpected patterns: excessive purchases, use of premium materials where standard options would suffice, and losses from expired products.

Optimization Strategies Without Sacrificing Quality

Cost reduction doesn’t mean switching to the cheapest materials indiscriminately. Improper savings lead to the opposite effect: customer complaints about leaking packaging, the need to use two bags instead of one quality bag, and staff time lost working with inconvenient materials.

Start by differentiating touchpoints — moments of customer contact. Packaging that leaves the establishment directly affects brand perception. Savings here should be cautious: a leaking container or soggy bag creates a negative experience. Conversely, back-of-house operation supplies — parchment for lining trays, gloves for prep work, trash bags — allow for more aggressive optimization since customers don’t see them.

Practical approaches to cost reduction:

- Size standardization — using fewer package sizes reduces inventory and allows ordering larger batches at better prices.

- Testing alternatives — systematically replacing one item at a time allows evaluating customer and staff reactions without risk to the entire operation.

- Portion optimization — the right container size for each dish prevents excessive packaging material waste.

Bulk purchasing only works for items with predictable consumption and sufficient shelf life. Economic feasibility calculations must account not only for unit price differences but also for storage costs, spoilage risks, and the possibility of freezing working capital.

Choosing a Supplier: Balancing Price and Reliability

Unit price is just one element in the equation. Delivery reliability, delivery speed, minimum order volume, return conditions, and customer service quality — all these factors affect the real cost of partnership. A missed delivery on Friday evening before a busy weekend can cost thousands of dollars in lost revenue, completely negating savings from low prices.

Regional suppliers often offer advantages that aren’t obvious when comparing price lists. Territorial proximity means faster deliveries and the possibility of emergency orders, local warehouses ensure assortment stability, and personalized service allows resolving issues directly without corporate bureaucracy.

Companies like McDonald Paper & Restaurant Supplies, serving the New York market for over two decades, know the specifics of local establishments and can offer solutions optimized for regional needs and logistical features.

Criteria for evaluating potential suppliers:

- Delivery geography and frequency — the ability to receive orders several times a week reduces warehouse space needs.

- Minimum order requirements — high minimum order amounts can be problematic for small businesses with limited space.

- Assortment — the ability to purchase different categories from one supplier simplifies logistics and often provides access to volume discounts.

- Payment terms — payment deferrals are critical for cash flow management.

Working with multiple suppliers diversifies risks but increases administrative burden. The optimal model for a small business is one primary supplier for most needs and one or two alternatives for specific items or as backup options.

Long-term Procurement Planning

A reactive approach — ordering when something runs out — leads to constant stress, emergency orders at inflated prices, and periodic situations when needed materials aren’t available at critical moments. Planning purchases based on historical consumption data transforms chaos into a predictable process.

A simple tracking system with weekly consumption of each item over the past several months allows identifying patterns and calculating average consumption. Most disposable supplies demonstrate seasonal fluctuations: summer increases demand for cold beverage delivery packaging, and winter increases demand for hot soups in containers. Understanding these cycles allows ordering in advance, often at better prices.

Establishing par levels — minimum stock quantities for each item — creates triggers for automatic orders. When napkin inventory falls below the established level, a replenishment order is initiated. This eliminates the human factor and the risk of forgetting to order critical items.

Smart Procurement Management as Competitive Advantage

Optimizing disposables procurement isn’t an accounting exercise but a strategic tool for increasing competitiveness. Freed-up funds can finance marketing activities, menu improvements, and salary increases for key employees — investments that directly impact business growth.

Small businesses cannot compete with large chains in negotiating power or purchasing volumes. But a competent supply strategy built on a detailed understanding of one’s own needs, careful partner selection, and a systematic approach to planning creates sustainable advantage. Every dollar saved on disposables is a dollar working toward development and strengthening market position.