If you’ve ever stripped wires by hand, you know the struggle—it’s slow, tedious, and often leaves you with sore hands and wasted materials. For businesses and DIYers who regularly deal with scrap wire, this inefficiency translates into lost time and missed opportunities for profit. That’s where a wire stripping machine comes in. Designed to make the process faster, cleaner, and more profitable, these machines are a smart investment for anyone working with copper, aluminum, or other wiring.

The Problem with Manual Wire Stripping

Stripping wires with a knife or handheld tool might work in small batches, but it quickly becomes impractical for larger jobs. Manual stripping:

- Takes too much time, especially with bulk wire.

- Produces inconsistent results, with some wires ending up damaged.

- Poses safety risks, from cuts to repetitive strain injuries.

The end results? Slower turnaround, wasted copper, and lost profits.

What Is a Wire Stripping Machine?

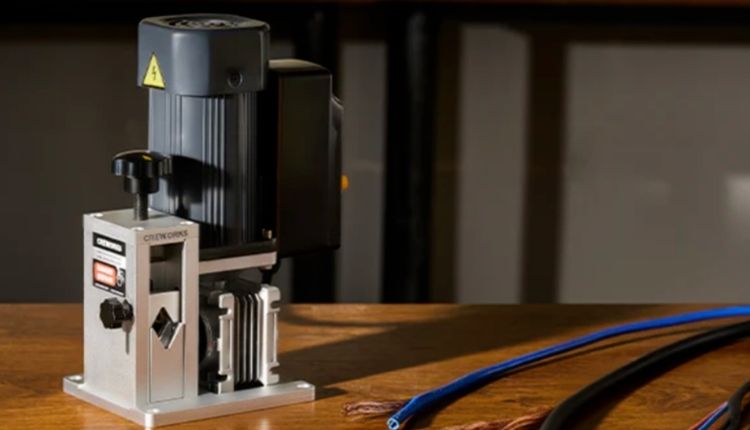

A wire stripping machine automates the process of removing insulation from electrical wires. Using adjustable blades and a feed system, it separates valuable copper or aluminum from the outer coating with speed and precision.

There are different types available:

- Manual crank machines – Affordable, great for small-scale users.

- Electric machines – Faster, ideal for workshops and contractors.

- Industrial-grade models – Designed for recycling centers and high-volume operations.

No matter the type, the goal is the same: save time and recover the maximum amount of metal.

Key Benefits of Using a Wire Stripping Machine

- Time Savings

What used to take hours with a knife can now be done in minutes. - Consistency

Every wire is stripped cleanly, with minimal waste or damage. - Profit Maximization

Copper and aluminum sell for more when stripped. A machine ensures you get the highest return on your scrap. - Safety

Eliminates the hazards of blades and manual force, making the process safer. - Versatility

Many machines handle different gauges and insulation types, making them adaptable to various needs.

Real-World Applications

Wire stripping machines aren’t just for big factories—they’re useful across many fields:

- Scrap Metal Recycling: Turn scrap wire into pure copper for resale at top market value.

- Electrical Contractors: Speed up job prep by processing wires quickly.

- Manufacturing & Workshops: Improve workflow efficiency and cut labor costs.

- DIY Enthusiasts: Recycle or repurpose wires at home without the hassle.

Choosing the Right Wire Stripping Machine

Not every machine is built for the same workload. Consider:

- Volume of wires – Occasional use vs. daily operation.

- Wire types – Coaxial, multi-core, or heavy-duty cables.

- Operation style – Manual crank or powered electric.

- Budget vs. ROI – A slightly higher upfront cost often pays for itself quickly.

If you process scrap regularly, an electric machine usually delivers the best long-term value. Brands like Creworks wire stripping machines are a solid choice for both professionals and DIYers—they’re built to handle different wire sizes efficiently, deliver consistent results, and pay for themselves quickly through increased copper recovery and time savings.

How Wire Stripping Machines Pay for Themselves

Think of it as an investment, not just a purchase. For example:

- Stripping 100 lbs. of copper by hand could take hours or even days.

- With a machine, the same job is done in a fraction of the time—leaving you with more copper ready for resale.

Over weeks or months, that saved time translates directly into higher profits. Most users find that their machine pays for itself after just a few big jobs.

Conclusion

Manual wire stripping might work in a pinch, but it’s no match for the efficiency, safety, and profitability of a wire stripping machine. Whether you’re recycling scrap, running a contracting business, or tackling DIY projects, this tool can help you save time and maximize profits.

If you’re ready to take your productivity to the next level, investing in a wire stripping machine could be one of the smartest decisions you make.